A wheel alignment machine is important in the automotive industry. It is necessary to align vehicle wheels. It ensures a vehicle’s wheels are perfect and the vehicle goes straight.

It aligns wheels to work better and go in the right direction after operating the vehicles.

This article delves into the details of alignment machines. It covers their types and their importance in vehicle care.

What is an Alignment Machine?

An alignment machine adjusts the suspension angles of a vehicle. These angles are called toe, thrust, camber, and caster. They affect tire movement and position.

It also ensures the steering wheel is centered. Alignment machines prevent uneven tire wear. This wear can make vehicles perform poorly and use more fuel.

Types of Alignment Machines

Several types of alignment machines are available in the market. Each has unique features and specs. Here are a few examples:

Manual Wheel Alignment Machine: This type of machine requires manual operation. It is a cost-effective solution for small-scale garages and workshops.

Wheel Alignment Machines are automatic. They have features that make the process faster and more precise.

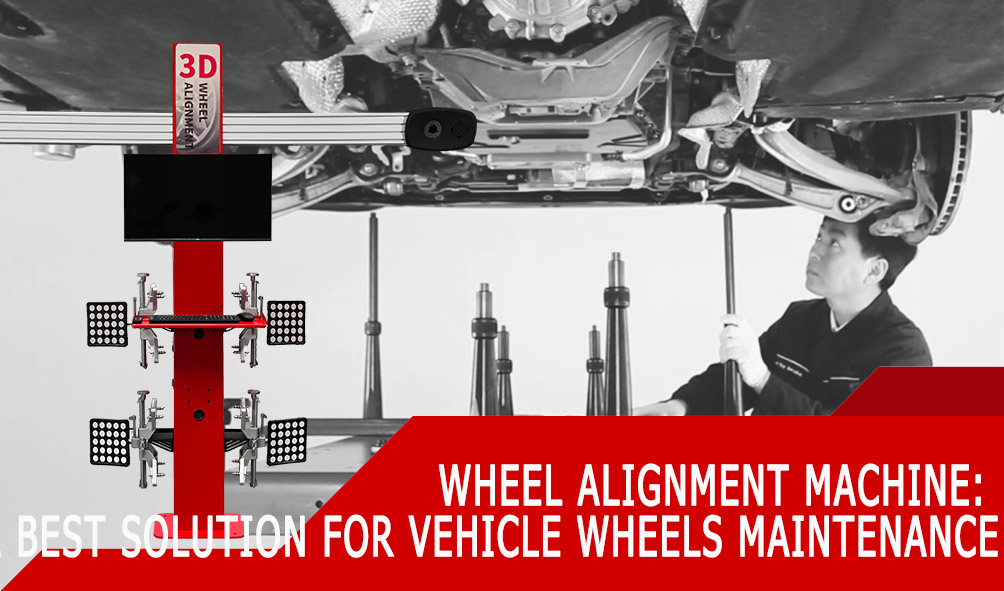

3D Wheel Alignment Machines use advanced 3D technology. They provide precise measurements and adjustments.

How Does an Alignment Machine Work?

Old alignment machines are large. They need an alignment lift, console, and sensors to work. However, modern technology has allowed wheel aligners to stay very accurate. They have also shrunk a lot.

The process begins by placing the vehicle on the alignment machine. The machine then uses its sensors to measure the current alignment of the wheels.

These measurements are compared to the vehicle manufacturer’s specifications. If any errors are found, the machine guides the mechanic. It tells them to make the changes to the car’s suspension.

Summary is here

In conclusion, an alignment machine is a very important tool in the automotive industry. It ensures the long life of a vehicle’s tires and makes the best mileage vehicle.

It also boosts fuel efficiency and gives the driver a smooth ride. It’s a manual, automatic, or 3D alignment machine.

Each plays a big role in keeping a vehicle healthy. Technology continues to change. We can expect more advances in alignment machines. This will make vehicle maintenance faster and better.

How to start a side income business?

If you are thinking to start a side income business with a low budget, then the automotive industry is the best option for you.

You can open a auto repairing garage for vehicles like automobiles, cars, autos, bikes, and trucks. Because these are such businesses which are growing day by day.

You can start a good business by making one time investment in these like wheel alignment setup, PUC Centre, Car washing setup. You can contact Unitequipment.

Unitequipment is the biggest automobile garage tools and automotive equipment manufacturer and seller since 2005 over the China and some specific countries. Unitequipment has 5 Lakh + happy Customers.

Wheel Alignment FAQ’S:

There are several types of alignment machines. They include manual, automatic, and 3D machines.

How does an alignment machine work?

An alignment machine uses sensors to measure the current alignment of the wheels. These measurements are compared to the vehicle manufacturer’s specifications. If any errors are found, the machine guides the mechanic. It tells them to make the needed adjustments to the vehicle’s suspension.

Why is machine alignment necessary?

Vehicles must be aligned. It alignme vehicles wheels for going straight and make vehicle work smoothly. It also improve vehicle mileage. If your vehicle not aligned then, It causes bad vehicle performance and lower fuel efficiency.

What are the effects of machine misalignment?

Misalignment can damage the machine, parts, and/or products on the line. When shafts are not aligned correctly, they rub. This uses more energy to power the machine. This rubbing together causes friction, which can lead to thermal stress.